12inch Underground T45 Drill Rod For Sale

The technical information of T45 12inch Underground Drill Rod usually includes information on its design characteristics, material properties, usage scenarios, size specifications, connection methods, and maintenance. Here is a simplified overview of technical materials:

Design features

High strength: T45 drill rods are designed to withstand high torque and tensile and compressive stresses, ensuring stability and durability during the drilling process.

Wear resistance: The surface of the drill pipe has been specially treated to improve wear resistance and extend its service life.

Corrosion resistance: using corrosion-resistant materials or surface coatings to adapt to various complex geological environments.

Material properties

High quality alloy steel: T45 drill rods are usually made of high-strength alloy steel to ensure their strength and durability.

Heat treatment: Drill pipes may undergo heat treatment to enhance their mechanical properties, such as tensile strength and yield strength.

Usage scenarios

Geological exploration: used for various geological exploration projects, such as drilling for oil, natural gas, and mineral resources.

Basic engineering: Used in foundation treatment of buildings such as bridges and high-rise buildings.

Water well drilling: applied in projects such as civil water wells and agricultural irrigation wells.

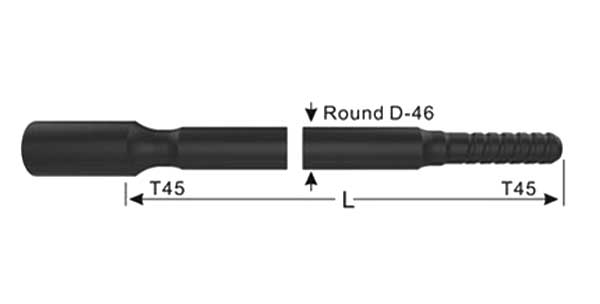

Size specifications

Length: 12 inches (304.8 millimeters)

Diameter: The specific diameter may vary depending on the application requirements, but T45 usually refers to a certain specification or type of drill pipe.

Thread specifications: The drill pipe is usually equipped with standard thread connections at both ends to ensure compatibility with other drilling equipment.

Connection method

Thread connection: The drill rods are tightly connected through threads to ensure stability and continuity during the drilling process.

Quick connection system: Some T45 drill pipes may be equipped with a quick connection system to improve connection efficiency and safety.

Maintenance and upkeep

Cleaning: After use, the surface of the drill pipe should be promptly cleaned of soil and impurities to avoid corrosion.

Lubrication: Apply an appropriate amount of lubricant to the threaded connection to reduce wear and friction.

Inspection: Regularly inspect the wear and damage of drill pipes, and replace or repair them in a timely manner if necessary.

Storage: Store in a dry, ventilated, and dust-free environment, avoiding prolonged exposure to damp or corrosive environments.